What is the rubber extrusion process?

The process is used by the manufacturing of rubber products under which the rubber material is converted into different shapes of the product so that it can have various applications.

How do you get the extruded rubber products?

You can get extruded rubber products by using an extruded rubber machine. The two major parts of the device include the shearing screw conveyor and the shaping die.

For the manufacturing of rubber products by the use of extrusion, the raw rubber is put inside the screw. Then it needs to get inside and then get additional heat inside the conveyor.

The stock then moves towards the conveyor from the hopper. Inside the hopper, the rubber gets soft by the process of shearing and heating.

When the rubber is soft enough, it is pushed through the opening in the die, where it receives the desirable shape. After getting the shape, the new shape emerges on the other end of the extruder.

Once this process gets complete, the rubber also receives the second processing method. The second processing includes steps like dusting and vulcanization.

Under the dusting procedure, the powder is put on the rubber so that rubber products in India can adhere to other materials. Under the process of vulcanization, rubber is cured with compounds like sulfur.

This helps in strengthening the extruder rubber products. Other secondary methods include drilling, cutting, splicing, and coiling.

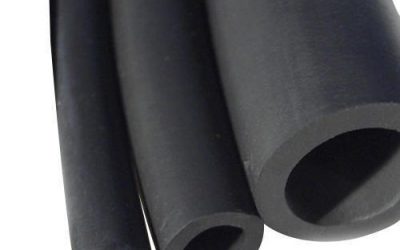

Applications of extruded rubber

For more than 30 years, extruded rubber products has been used for different purposes across different industries.

These rubbers have applications for purposes like seals, edging trims, dunnage, and bumpers. The best part about the extruded rubber is that it is highly elastic and flexible.

Therefore, it can have various industrial applications. These rubber types can also absorb shock, offer better sealing capability, and it is also resistant to heat.

Extruded rubbers are also available in different shapes, lengths, and styles. Each style can meet specific requirements.

Following are some of the significant extruded rubber products.

– Rubber Bumper

This device is useful in absorbing shock that is produced between two different objects.

Benefits of using extruded rubber

● The use of extruded rubber offers maximum protection and also gives proper ventilation and spacing.

● It is useful in controlling vibration.

● Improves the momentum at the time of the collision

● Available in different colors and quality.

– Rubber Bushes

Rubber bushes are cylindrical, and it has an inner and outer layer made up of metal.

Benefits of using extruded rubber:

● The bushes can withstand the torsional movement.

● It can improve the durability of the bush.

● It can help suppress sound as well as vibrations.

● It can be useful for improving friction.

● The use of extruded rubber can help reduce wear and tear.

– Rubber Cord

Rubber cord is one of the best choices for the cord when it comes to bungee jumping. The cable can be stretched up to four times its actual size.

Benefits of using extruded rubber:

● Highly resistant

● Offers maximum flexibility to the cord

● The rubber is resistant to all types of temperature and weather conditions.

● The use of extruded rubber helps in the prevention of abrasion.

Benefits of extruded rubber?

There are numerous benefits of rubber extrusion. You can manufacture different types of products from the extruded rubber.

The process of extrusion enables businesses to get rubber products in different shapes and lengths. In addition to this, you can also cut rubber for various applications. This process is highly efficient.

Most people also use the rubber molding process. But, this process is costly as compared to the extrusion process. In addition to this, the rubber molding process is also limited in application.

This is because of the size of the manufacturing press used. The rubber sheets are available in numerous in height and length.

The molding machines are also relatively cheaper, and hence it is best for cost-effective productions. The extruder is also helpful in maintaining greater accuracy, unlike the stripped products.

Another significant benefit of an extruded rubber is that it can have lots of applications.

The following are some of the significant benefits of an extruder rubber-

– High Quality

Extruder rubber offers long-lasting quality. Under the manufacturing process, high-quality rubber and blending compounds are in usage.

Thus, the extruded rubber products can offer products to the customer that have long-term benefits.

For example,

if you purchase a gasket made up of extruded rubber, you will attain lots of benefits. The gasket will be highly resistant to heat, cold, ageing, different types of friction, abrasion, and wear and tear.

Thus, the gasket will work for a longer duration. So, if you order a gasket made up of an extruded rubber, you will get the guarantee to get flawless services for a long time.

– Resistance to wear and tear

If you purchase extruded rubber products from a quality manufacturer, they use an innovative method of manufacturing.

Thus, you will be able to get long-term wear resistance for the rubber. For example, most manufacturers use polypropylene, which is a Teflon-based tape, and thus, it gives a high-temperature wear resistance.

In addition to this, sometimes Polyethylene is also put in practice in the extrusion process that works as a dual durometer.

In some instances, manufacturers also use spray, wipe, and low-friction coating to enhance the durability of the rubber.

– Extra savings of money

You can also get to save and spare extra money by using the extruder rubber. Less amount of material gets wastage when you use the rubber extrusion process.

This means you can easily save extra bucks. In addition to the reduction in the amount of wastage, the production, as well as maintenance cost are comparatively low when it comes to the usage of extruded rubber.

This means, in the case of an extruded rubber, the manufacturer and the customer get an option to save extra bucks.

So, if you are thinking of getting high-quality rubber, but you want to save money, choosing extruder rubber can be the best choice you can make.

– Variety

One of the most significant advantages of using an extruder rubber is that you can produce a variety of products as per your requirement.

You can get rubber extrusion in a variety of lengths, shapes, and compounds that can work under different temperature and weather conditions.

There is a high demand for extruded rubber in different types of industries. The extruded rubber is different from other rubber types, and it offers maximum benefits.

The rubber is in maximum demand these days as it is sturdy, has fine finishing, and is also resistant to heat. It is applicable for major industrial applications as it can easily absorb shocks, offers better sealing capability, and is also resistant to heat.

Since these rubber types are available in different designs and styles, they provide multiple usages.

Before you purchase extruded rubber, make sure to get details about it. We are hopeful that this article will help you understand the nitty-gritty of extruded rubber products. Let us know if you want to get more details.

Also, choosing the right rubber manufacturing company is crucial. A lot of companies have preferred R-Tech Industries. R-Tech Industries is one of the leading and top-rated Rubber Products Manufacturers In India.

7 Benefits of using silicone rubber for window and door seals

Home Blogs 7 Benefits of using silicone rubber for window and door sealsA silicone rubber sheet is an elastomer made up of silicone-...

Advantages of EPDM sponge rubber

Home Blogs Advantages of EPDM sponge rubberOver the years, EPDM has become extremely popular. More and more people are using it for...

5 Benefits of Rubber Products to The Marine Industry

Home Blogs 5 Benefits of Rubber Products to The Marine IndustryRubber products are being adopted against different industrial...

Locations

R Tech Rubber Industries : Rubber Products Manufacturers

📍- Raju Industrial Estate, 16 / A, near Western Express Highway, opp. Imperial Heights Building, Penkarpada, Mira Road East, Mumbai, Mira Bhayandar, Maharashtra 401107

📞- 09820030660

R-Tech Rubber Industries © 2021 All rights reserved