Over the years, EPDM has become extremely popular. More and more people are using it for different purposes from shooting to roofing and so much more.

EPDM is a synthetic rubber that has impeccable chemical properties. These are responsible for weathering resistance and providing high-quality performance.

However, these cannot work with fuels and oils. R-Tech Rubber has some of the best EPDM sponge rubber sheets.

What is EPDM?

EPDM rubber is the short form of Ethylene Propylene Diene Monomer of the M-class. It is an elastomer popular mostly for its different uses.

The M of M class is stated because it belongs to the ASTM standard D-1418. The M class consists of all rubbers belonging to a saturated strain of the polymethylene type.

Where is the EPDM sponge sheet used?

EPDM sponge rubber sheets are used for different purposes. The sheets have water-resistant characteristics, for salt as well as freshwater. This provides extreme benefits against UV oxidation and ozone. Furthermore, EPDM sponge rubber sheets have weather and temperature-tolerant capacity.

It is also one potential medium for resisting water. As a result, EPDM sponge rubber may be used as a potential application in terms of electrical cable joints, roofing membranes, plastic impact modification, geomembranes, roofing membranes, vulcanizates, and more.

What are the properties of EPDM?

The main properties of EPDM include withstanding heat, ozone and being resistant to weather. EPDM sponge sheets and rubber also have great insulating characteristics.

They are also resistant to ketones and alkalis and acids. Many times, EPDM sponge sheets are used for electronic, automotive and construction purposes.

What are the advantages of EPDM sponge rubber?

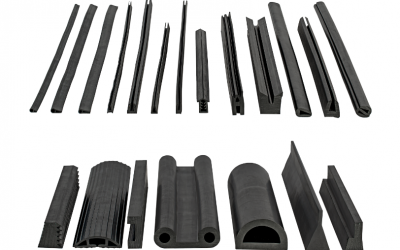

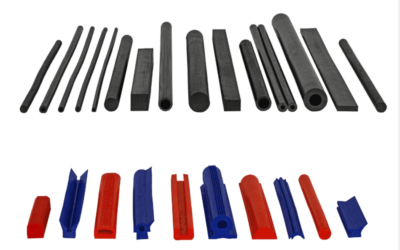

EPDM sponge rubber can assist in different purposes because of its versatility. Moreover, the properties of it have already made it an extremely popular material. Some of the prominent advantages of EPDM sponge rubber include the following.

– Versatile

One of the greatest benefits of an EPDM sponge sheet is its versatility. The sponge rubber sheet can easily fit into the requirements of different industries.

– Light

EPDM is lighter than other types of rubber. It is for the lightweight property that many companies prefer EPDM sponge rubber gaskets as the end product. Furthermore, it will last a long time, which is why it can be used for different reasons.

– Acts as a thermostat elastomer

Because of its property to act as a thermostat elastomer, EPDM sponge rubber sheet can be modified into different activities. It is further used in low temperature to maintain UV stability. Because of its heat, compression and crack resistant characteristics, it is one of the best materials across different fields. Furthermore, it is also extremely flexible and can offer high strength too.

– Garage door seals

Because of its high thermal insulation characteristic, this is used for garage door seals as well.

Some of the other benefits of EPDM sponge rubber include the following :

- Extremely affordable.

- Closed-cell structure.

- Great ageing characteristic.

- Available for a high-temperature range.

- Available in a variety of thickness ranges.

- Long-lasting

What are the industries in which EPDM is used?

EPDM rubber is used widely across different industries. However, one of the main reasons EPDM is used at such a massive scale is that it is cheaper than silicone rubber.

EPDM rubber is also used as roofing or liners. But, the four main industries which benefit the most from EPDM rubber include the following.

– Automotive

EPDM sponge rubber is used extensively in the automotive industry because of its flexibility, weather ability and resistance.

The sponge rubber is usually attached across sealants, wire, cable harnesses, brake systems and seals. The EPDM sponge rubber is also mixed with different materials for making car bumpers, fender extensions and rub strips.

– HVAC

EPDM sponge rubber is used very much in the HVAC industry. However, it is used in different forms like seals, insulations, gaskets, grommets, because it has high-temperature durability.

– Industrial

EPDM is insulated to electricity and has waterproofing characteristics. This plays an important role in increasing resilience.

Furthermore, EPDM sponge rubber is found in different water systems like hoses, gaskets, O-rings, electrical insulators, and connectors. The flexibility of EPDM makes it capable of taking up the shape of belts, accumulator bladders, grommets and diaphragms.

– Construction

Because of the weather-proof and insulating characteristics, EPDM sponge rubber is used extensively in the construction industry. The water-resistant capacity makes it beneficial for roofing.

Apart from that, EPDM rubber is also used as sealant, pool and tank liners, coating for bitumen roofs. In many cases, it is also used for RV roofs.

What is the difference between EPDM and silicone?

EPDM and silicone are synthetic rubbers, but the main difference between the two lies in how they’re used.

Silicone serves general purposes while EPDM caters to the needs of specific purposes. However, both are resistant to ozone, UV, and weather while catering to the need to have a good bond with the metal.

Silicone is extremely flexible in terms of application, but it is also costly, so not everyone prefers it. What’s better about EPDM is that it can function under high temperatures.

Silicone can serve the purpose of food safety, which is not the case with EPDM. Moreover, silicone has a better compression set and a longer lifespan than EPDM.

EPDM is a specialized rubber that is inexpensive and tends to function better than silicone.

Both EPDM and silicone are waterproof, but silicone smells are exposed to water, while EPDM’s smell is retained.

Compared to EPDM, silicone is more resistant to steam and can withstand steam up to 392°F without any air.

Takeaway

EPDM is extremely beneficial and can help you in the long run. However, it is necessary to ensure that EPDM caters to your industrial needs. Make sure to purchase EPDM only from experts.

Choosing the right rubber manufacturing company is crucial. A lot of companies have preferred R-Tech Industries. R-Tech Industries is one of the leading and top-rated Rubber Products Manufacturers In India.

Difference between EPDM and Nitrile Rubber

Home Blogs Difference between EPDM and Nitrile RubberSynthetic rubber is an artificial man-made elastomer that is used in a vast...

Sponge Rubber vs Solid Rubber: What’s the difference?

Home Blogs Sponge Rubber vs Solid Rubbre: What's the difference?One of the most commonly asked questions is what is the difference...

Application and Benefits of Molded Rubber Products

Home Blogs Application and Benifits of Molded Rubber ProductsThe inescapability of rubber around us as different parts, materials,...

Locations

R Tech Rubber Industries : Rubber Products Manufacturers

📍- Raju Industrial Estate, 16 / A, near Western Express Highway, opp. Imperial Heights Building, Penkarpada, Mira Road East, Mumbai, Mira Bhayandar, Maharashtra 401107

📞- 09820030660

R-Tech Rubber Industries © 2021 All rights reserved